3 Benefits of a Portable Push-Lok Hose Assembly tool

Take the PUSH out of Push-Lok

Anytime you chat with an operator or a maintenance repair operations (MRO) specialist who has spent hours and months assembling Push-Lok fittings without a hose assembly tool, there is one common response: UGH.

Assembling a Push-Lok fitting or two isn’t an issue. The manual brute force of assembling a few during the course of day is manageable

Now think about one or two HUNDRED.

What goes through your head if you were asked to assemble 200 Push-Lok fittings by hand, without an assembly tool, in the next 8-hour shift to fulfill a rush job?

If you’re like any of the MRO specialists we’ve talked to, that thought process probably included everything from displeased grunting and 4-letter expletives to nightmarish images of destroyed hands and knuckles and a looming workers’ comp claim.

But that doesn’t have to happen if you use the right tool for the job.

Enter the portable push-lok hose assembly tool

“What goes through your head if you were asked to assemble 200 Push-Lok fittings by hand, without an assembly tool, in the next 8-hour shift to fulfill a rush job?“

Benefit #1: A portable hose assembly tool makes things safer.

Ensuring safety during the maintenance and retooling of a pneumatics configuration is a priority in maintenance, repair and operations.

To ensure operators actually use an available assembly tool, ease of use, reliability, and portability are important. If an operator needs to remove both ends of a hose installation, move to a bench hose assembly tool then return to the job site, let’s face it.

It’s probably not gonna happen.

That’s more time consuming, and the likelihood of workers using the bench mounted tool is low. If the tool comes to the job, that’s another story.

Benefit #2: Push-Lok tools make assembling fittings easier and faster.

Push-Lok hose assembly tools also make it easier and faster to install the hose fittings. The fittings in a pneumatic system have a barb component to grab the hose, creating a secure connection that—once installed—isn’t removable.

The nature of the barbs and tight fitting of the hoses makes the assembly process tedious. This is especially true of smaller diameter hoses, not to mention all of the various shapes and sizes of push-lock fittings that make things tricky. Elbow fittings (90- or 45-degree angled fitting) are rounded on the elbow side, leading to difficulties and possible incorrect assembly.

Benefit #3: Having the right tool reduces risks of damage (to people and equipment).

At Barb-Tech™ tools, we’ve heard all types of methods to simplify the assembly of Push-Lok fittings:

- Holding the fitting in a vise and pushing the hose onto the fitting

- Leveraging a wall or a table to push the hose on

- Using an oil-based lubricant or grease to assist in the seating of the hose

All of these run the risk of damaging your equipment and causing injury.

First, doing this all day long increases the likelihood of a slip and injury to the operator’s hand. Taking these shortcuts can also result in fittings being incorrectly installed, resulting in a risk of future blow outs. That can cost you both time and money. Lastly, contaminating your hose line with an oil-based product, when you need to ensure a clean line for air or gas, can also cause major problems.

Other worker-related risks increase with certain work environments. Where dismantling the entire system to reach the end of a connection is not possible, maintenance operators must get creative to complete the job, increasing their risk of fall and injury in the process. We’ve even heard stories of operators on ladders to manually assemble push lock fittings!

3 solutions, 1 tool

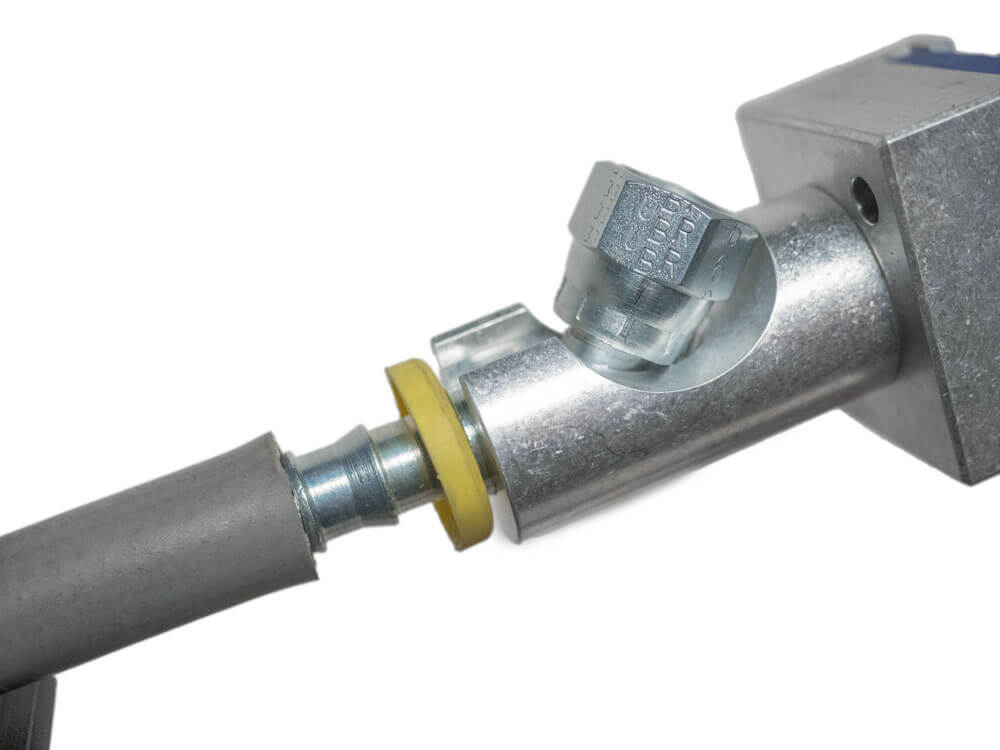

Barb-Tech™ Tools addresses worker safety, efficiency, and ease of use with a portable solution to bring directly to the job site. It has a combination of a mandrel that holds the push lock fitting and a jaw-style mechanism, like the rope cleat system on a sailboat, to guide the hose.

Barb-Tech™ Tools’ hose assembly tool allows an operator to ensure the hose seats and guides accurately into the fitting without using brute force to push the hose and fitting together–saving your hands and knuckles from the slips.

By using a Barb-Tech™ Push-Lok assembly tool, you:

- Ensure the hose and fitting are correctly installed

- Reduce pressure on the operator’s hands when applying the force

- Enable workers to assemble hoses on site when it is impractical to work from a bench mounted system

Ready to take your hose fittings by the horns? Barb-Tech™ Tools’ Push-Lok hose assembly tool is available here: Barb-Tech IIc